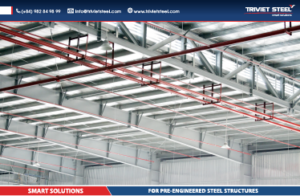

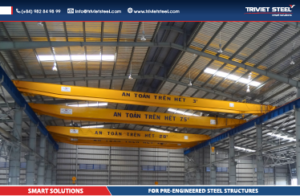

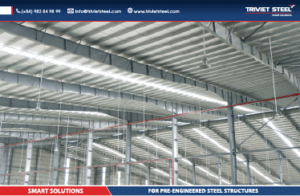

SẢN PHẨM

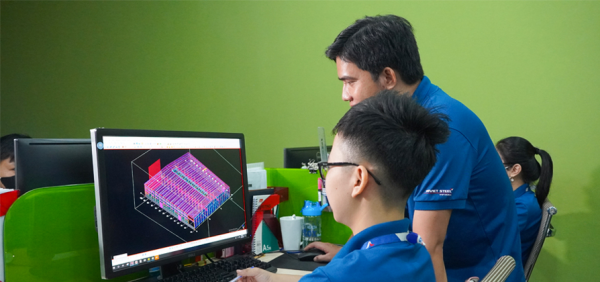

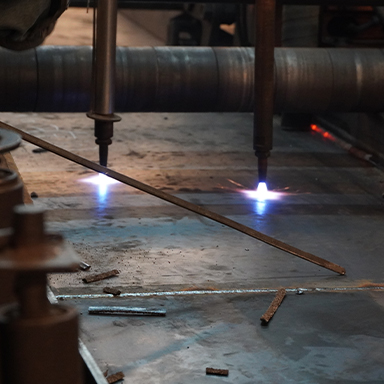

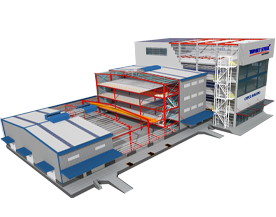

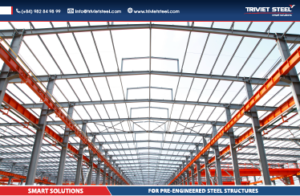

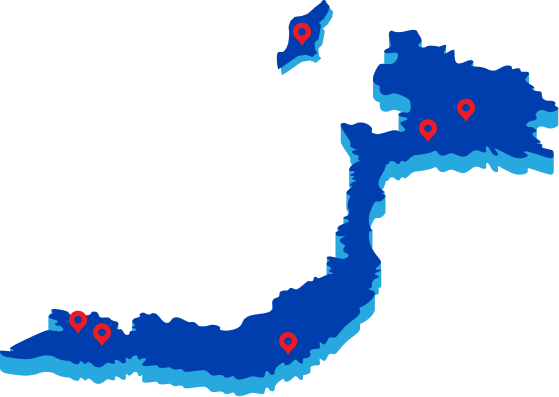

Với sản phẩm đa dạng và dịch vụ hoàn hảo, Nhà Thép Trí Việt đã và đang đáp ứng nhu cầu ngày càng tăng của khách hàng. Chúng tôi tự hào là nhà cung cấp “giải pháp thông minh” thuộc top Nhà Thép Tiền Chế hàng đầu tại Việt Nam.

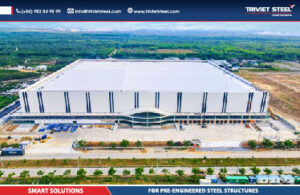

DỰ ÁN NỔI BẬT

Xem thêm

TIN TỨC

Các tin tức nội bộ, hoạt động sự kiện tại Nhà Thép Trí Việt, các thông tin hợp tác quốc tế, thông tin dự án và thị trường kết cấu thép được cập nhật thường xuyên

KHÁCH HÀNG & ĐỐI TÁC

Sự thành công của Nhà Thép Trí Việt hôm nay tất cả nhờ sự tin tưởng, hổ trợ và đồng hành từ quý đối tác và khách hàng

Nhà máy

02

Năng lực sản xuất

36000

+ (tấn/năm)Kỹ sư & nhân viên

550 Tiếng Việt

Tiếng Việt English

English